- About D-Link

- Products and Services

- ESG

Sustainable Development

Sustainable Supply Chain

Sustainable Workplace

For Stakeholders

- Investor Relations

- News Room

- Careers

Supply Chain Management

Home > ESG > Sustainable Supply Chain > Supply Chain Management

Suppliers are the driving force behind D-Link’s competitive edge. By implementing due diligence, D-Link leverages its market influence to enhance the sustainable value of the overall industry chain and improve the value chain management strategies of its upstream and downstream partners. Through long-term and stable collaboration, D-Link reduces operational risks and costs, provides reliable and high-quality products and services to customers, and achieves sustainable supply chain management.

Overview of Main Suppliers

D-Link is a brand company, its business scope does not include manufacturing, and its products are all commissioned to suppliers. Currently, there are 7 main OEM suppliers for D-Link products.

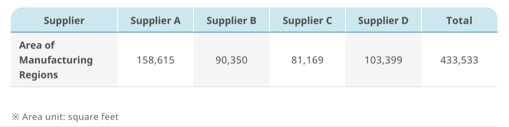

D-Link does not have a production department. Calculated based on the four main suppliers who accounted for over 50% of D-Link’s total procurement in 2024 and the number of products produced, the total manufacturing area is approximately 433,000 square feet, and the distribution is as follows :

Local Procurement

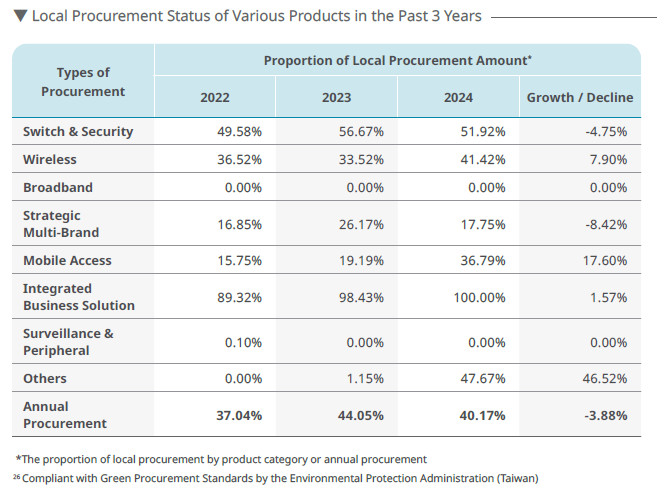

The key material used in D-Link products is active components, particularly integrated circuits (ICs). To mitigate the risk of supply instability, the Company actively develops multiple sources of supply, regularly reviews sourcing distribution, and intentionally maintains a certain proportion of local suppliers to ensure effective control and flexible responses. Based on this strategy, D-Link has been increasing the proportion of locally sourced components made in Taiwan. In 2024, due to inventory level adjustments and supplier integration policies, the proportion of local procurement slightly decreased by 3.88% compared to the previous year. Looking ahead, the Company is committed to continuous growth in this area.

Supplier Classification Management System

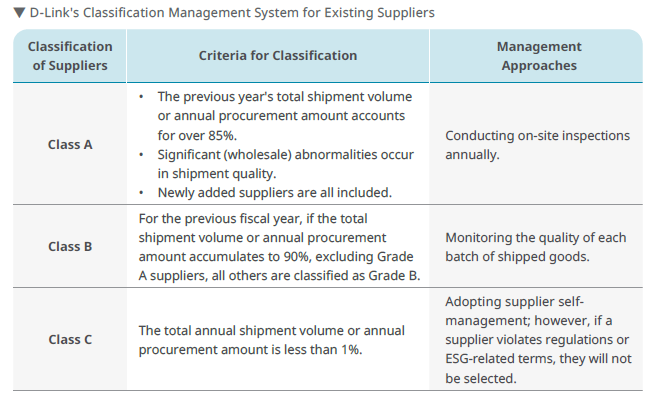

D-Link offers a diverse line of products. In 2025, 34 suppliers have been registered in the Company’s qualified suppliers list. The number of suppliers and the scale of cooperation often increase or decrease due to business growth and decline. In addition to conducting sustainable development issue surveys for new suppliers, D-Link also conducts a risk assessment and classification. Different audit strategies are regularly formulated for the different levels of risk to eliminate systematic risk.

2023 | 2024 | 2025 | ||

|---|---|---|---|---|

Number of New Supplier | 0 | 5 | 0 | |

Number of Suppliers Evaluated through On-site Audits | 0 | 3 | 0 | |

Number of Suppliers Passed On-site Audit Evaluation | 0 | 3 | 0 | |

New Supplier Audit Rate | - | 60% | - |

* In addition to basic audit criteria, it also includes indicators related to ESG aspects.

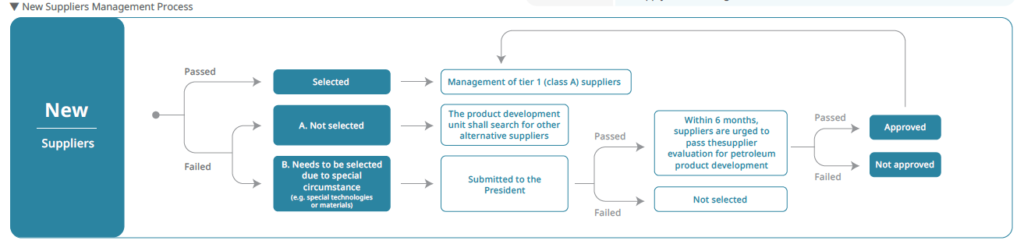

New Suppliers

D-Link has clear qualification requirements and review mechanisms for new suppliers in place. Through document review and on-site audit, the suppliers are verified that their quality and sustainable management systems have reached a certain level before being officially included in the Company’s supply chain system, to ensure the stability and sustainability of the entire supply chain.

D-Link’s Qualification Requirements for New Suppliers

Existing Suppliers

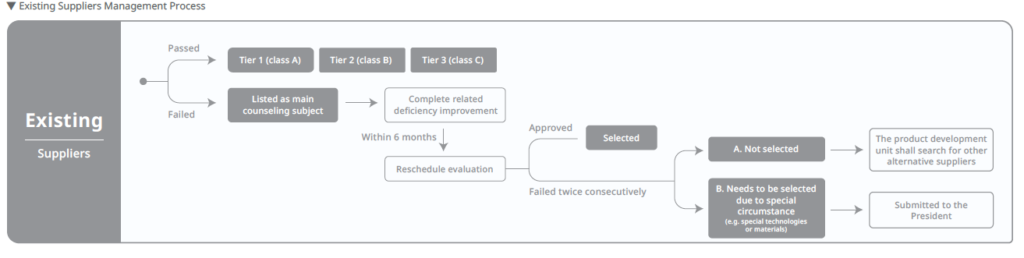

D-Link formulates an annual list of major suppliers according to specific criteria, implementing yearly quality management system, environmental health and safety, or labor integrity audits and driving improvements. Based on the evaluation results, D-Link identifies the risk levels of major suppliers, thereby formulating subsequent counseling plans.

Supplier Audit Status

D-Link takes the management scopes such as supplier quality, cost, delivery and services as the foundation. In recent years, it has extended the scope of supply chain management to ESG issues such as environmental protection and people. It expects suppliers to not only provide excellent products and services, but also monitor their social and environmental values and strive to implement energy saving, environmental protection, and environmental friendliness.

As the Company treats the suppliers as important partners for long-term cooperation, growth and development, D-Link complies with the principle of mutual benefit and common prosperity with suppliers, and refers to the requirements of the Code of Conduct by the Responsible Business Alliance (RBA), and addresses ESG related risks and impacts. The Company establishes the risk management and control projects based on the requirements for supplier selection and audit, and then formulates the improvement measures based on the evaluation results, to help suppliers improve continuously, reduce operational risks, and jointly promote the sustainable operations.

In order to build the capabilities of members in the sustainable supply chain, D-Link starts from four aspects : evaluation, counseling, communication and collaboration, and corresponds to the supply chain management structure, to ensure that relevant important issues have practical and executable procedures for effective management and control. In addition, responding to the trend of sustainable development, D-Link actively encourages suppliers to develop materials and processes that mitigate environmental impact, or to save energy and reduce carbon emissions from the shared equipment used in the process.

▼ Implementation Status of Supplier Sustainability Management Audits in the Past 3 Years

2023 | 2024 | 2025 | ||

|---|---|---|---|---|

Number of All Suppliers | 34 | 34 | 35 | |

Number of Major Suppliers1 | 7 | 7 | 9 | |

Number of Major Suppliers Conducting Sustainability Management Audits | 7 | 7 | 9 | |

Proportion of Major Suppliers Conducting Sustainability Management Audits | 100% | 100% | 100% |

* Suppliers accounting for 85% or more of the total procurement amount in the previous year are considered major suppliers.

D-Link requires suppliers to compile internal improvement opinions as soon as possible after receiving the on-site audit report and respond with specific, feasible improvement plans according to the actual conditions of their plants. If a serious quality abnormality occurs during shipping, the supplier must hold a meeting to confirm the cause of the problem and develop a solution, including how to dispose of finished products. Subsequently, the Company’s dedicated personnel will review the supplier’s audit improvement report and continue to track the improvement progress to ensure that the measures are implemented and the expected results are achieved.

In the key supplier evaluation in 2025, a total of 100 quality system deficiencies were found, mainly concentrated on negligence of the management system and process operation; four ESG deficiencies were found in health and safety, environment, labor, supply chain, and social ethics, mainly involving the management system and excessive working hours. Upon the follow-up review, some improvement plans have not yet met the Company’s defined qualifying standards and are still being improved during the reporting period, making the annual deficiency improvement rate 84.62%.

D-Link will continue to review and optimize the quality management process, environmental quality and personnel training mechanism with suppliers to improve product quality, reduce the occurrence of deficiency, while strengthening improvement effectiveness. Regarding the vendors performing poorly in terms of improvement, the purchase volume will be reduced gradually, to ensure that the supply chain operations meet the requirements of sustainable development.

▼ Audit Nonconformities and Improvement Rates in the Past 3 Years

2023 | 2024 | 2025 | ||

|---|---|---|---|---|

Sustainability Management | 12 | 5 | 4 | |

Quality Management | 125 | 84 | 100 | |

Defect Improvement Rate | 81.02% | 88.76% | 84.62 |

2025

Improvement rate of addressing deficiencies for suppliers: 84.62%

Number of suppliers listed as unqualified suppliers for violating social responsibility standards: 0

Reports on bribery of suppliers: 0

Home > ESG > Sustainable Supply Chain > Supply Chain Management

Home > ESG > Sustainable Supply Chain > Supply Chain Management

Supply Chain Management

Home > ESG > Sustainable Supply Chain > Supply Chain Management